charpy impact test results for a36 steel|charpy impact energy vs temperature : supermarket The rectangular grinding was filled with wet welding simulating seawater at depths of 50, 70 and 100 m. Standard Charpy specimens were extracted to obtain energy values. In addition, a .

web21 de jan. de 2023 · As informações e o palpite para West Ham x Everton. Em clima de decisão, West Ham e Everton, igualados na pontuação e afundados na zona de rebaixamento, terão seus caminhos cruzados neste sábado, 21 de janeiro. O confronto, que faz parte da agenda da vigésima primeira rodada do Campeonato Inglês, abre a chance .

{plog:ftitle_list}

WEBAline Füchter Ouriques. @AlineFuchterOuriques ‧ 1.78M subscribers ‧ 701 videos. Oi gente meu nome é Aline Füchter sou proprietária dos .

A Charpy impact test (CVN test) is used to measure the fragile-ductile temperature and as a quality control test. This evaluation's simplicity allows converting energy .© 2008-2024 ResearchGate GmbH. All rights reserved. Terms; Privacy; IP .Charpy V-notch test results revealed that the energy absorption ability of the 6061 .Charpy V-notch tests are performed on plain carbon steel at five temperatures. .

Charpy V-notch test results revealed that the energy absorption ability of the 6061-T6 Al alloy is roughly two times higher than the 2024-T4 and roughly four times higher than the 7075-T6 Al.

The rectangular grinding was filled with wet welding simulating seawater at depths of 50, 70 and 100 m. Standard Charpy specimens were extracted to obtain energy values. In addition, a .

In this investigation, we performed instrumented Charpy tests in order to characterize the impact properties of three steels, used by NIST for the production of Charpy reference specimens .One of the most dramatic results of Charpy impact tests is in the form of plots of impact energy versus temperature in which sigmoidally-shaped curves (see Fig. 3) show substantial .

By using Charpy impact energy (CVN), KIC values could be predicted by KIC-CVN correlations. In addition, correlations were presented to obtain KIC values in the lower shelf, .The Charpy LCVN model is statistically robust for ASTM A36, A516 Gr70 and A572 Gr50. The model agrees with metallurgical theory. C and Mo show a strong influence on Charpy impact . The capsule included six CVN impact specimens of archival High Flux Isotope Reactor A212 grade B ferritic steel and five CVN impact specimens of a well-studied A36 .

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact .Charpy V-notch tests are performed on plain carbon steel at five temperatures. The students evaluate the impact data by a CVN impact energy vs. temperature plot (see Figure 3 ), % shear.The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the . 2.3 Metallographic Characterizations. The specimens were well welded with double grooving of the butt joint. The cross-section of welded metal is shown in Fig. 3.The two specimens (34 mm × 30 mm × 4.5 mm) were welded by the ABSMAW and then the welded metals machined with (55 mm × 10 mm × 4.5 mm) according to the ASTM E23 (Charpy test) standard, as .

ASTM A36, A516 Gr70 and A572 Gr50. The model agrees with metallurgical theory. C and Mo show a . Does the model adequately predict Charpy impact test results? Is the model relatively easy to use? . certification to determine whether a steel plate would pass a Charpy impact test The coefficient for C was -915.354, which shows .• Charpy V-notch test specimens of 6061-T6 aluminum and 1018 (hot rolled) or A36 steel • Charpy testing machine with 800-mm long pendulum arm and 22.6-kg impact head • Type K thermocouple and digital readout unit . Compare these impact results for each metal to tabulated values from a source such as the ASM Metals Handbook. Comment on .

results from the Charpy impact test of the Titanic hull steel for the longitudinal and transverse rolling directions with a modern ASTM A36 mild steel [7]. Unfortunately for the purposes of a direct correlation of properties and microstructure, the comparison of mechanical behavior was

An exhaustive search through the literature of several authors was performed to collect experimental CVN data about wet welding being applied to A36 steel for comparison with CVN data obtained in this study. By using Charpy impact energy (CVN), KIC values could be predicted by KIC-CVN correlations.

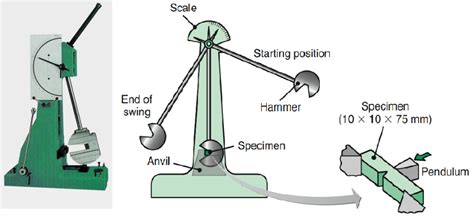

The results revealed that CVN values are proportionate to K IC, this data decreases as . Although this CVN impact test data does not represent the real fracture toughness . Fracture Toughness and Charpy CVN Data for A36 Steel with Wet Welding Soldagem & Inspeção. 2017;22(3):258-268 261The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.

Rubber Impact Resiliency Tester service

completed impact tensile testing results at -20oF conditions for dual-marked 304/304L and 316/316L stainless steel material specimens (hereafter referred to as 304L and 316L, respectively). Recently completed welded material impact testing at -20 oF, room, 300 oF, and 600 oF is also reported. Utilizing a drop-weight impact test machine and 1/4 .In addition, a search of Charpy CVN values using A36 steel and E6013 electrodes was performed with wet welding. Finally, K IC -CVN correlations were presented to measure the fracture toughness. As conclusions they drawn that CVN impact energy and K IC values decrease as the sea depth increases.

Yes, to your second question. The cold rolled will have slightly lower notch toughness, provided both steel plates were provided in the same heat treatment condition (hot rolled, air cooled). The problem with A36 with regards to impact properties is variability in impact values based on plate thickness, and steel making practice.lbf) 27 (20) Structural shapes, alternate .Constructing a building using steel beams that haven’t been tested for their ability to withstand sudden external forces could lead to catastrophic structural failure. By subjecting materials to Charpy Impact Testing, manufacturers and engineers gain invaluable insights into how various materials will respond to real-world operating .While Charpy results cannot be directly applied to structural design requirements, a number of correlations have been made between Charpy results and fracture toughness. Topics Charpy testing , Cast metal alloys , Wrought steel , Steelmaking , Alloy composition , Ductile-to-brittle transition temperature , Notch impact toughness

MATERIALS TESTING: CHARPY V-NOTCH IMPACT* . Charpy V-notch specimens of 6061 T6 aluminum and 1018 (hot rolled) or A36 steel Charpy testing machine with 800-mm long pendulum arm and 22.6-kg impact head . One of the most dramatic results of Charpy impact tests is in the form of plots of impact energy versus temperature in which sigmoidally . The Charpy impact test (CVN) is still the most widely used test for evaluating the absorbed energy and transition temperature of line-pipe steels because of its simple testing method and fewer . History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness .

Material Testing A36 & A572 Steel Plate. When used in colder environments, structural project engineers may request a Charpy impact test be performed on A572 and A36 materials. Charpy tests measure the ability of a material to withstand great forces within specific temperature ranges, which is crucial to ensure structural materials do not break or fail in harsh .

charpy impact test pdf

Estimation of fracture toughness K IC from Charpy impact test data in T-welded connections repaired by . T-welded connections were manufactured using ASTM A36 steel. Table 1 shows the chemical composition of the A36 steel, that is, the percent elements in mass. Rectangular grinding was at the weld toe in the T-welded connections .Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).Abstract A capsule containing Charpy V-notch (CVN) and mini-tensile specimens was irradiated at - 30°C (- 85°F) in the cavity of a commercial nuclear power plant to a fluence of 1 x 1 0l6 neutrons/cm2 (> 1 MeV).The capsule included six CVN impact specimens of archival High Flux Isotope Reactor A212 grade B ferritic steel and live CVN impact .

Rubber Flex Cracking Tester service

Charpy Impact Test Cold Formed Steel Hot Rolled Steel Temperature Conditions Toughness Resistance To Fracture Brittle Failures Tough Materials Charpy V-notch Test Notched Specimen Swinging Hammer Energy Absorption Fracture Surface Strong And Ductile Material Chemical Composition Material Processing Loading Situation Brittle Or Ductile Behavior.

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .

Charpy Impact Test Unit Fig. 1: Mechanical principle of the Charpy Impact Test device [2]. Results gathered from the Charpy Impact Test are important because they determine the right material for a specific application. The use of materials that do not meet the requirements can have fatal consequences. When coldness and strong force

3. Results and Discussion 3.1. CVN data. Table 3 presents the Charpy CVN values and σ YS of the material gathered by different authors who employed wet welding in ASTM A36 steel. It can be observed that Di Lorenzo [30 30 Di Lorenzo RF, Soares WA, Bracarense AQ.Fracture toughness of ferritic steel underwater wet welding. Proceedings of the 18th International .Charpy V-Notch Impact Testing ENGR45 – Materials Science Laboratory Chad Philip Johnson Submitted: May 15th 2013. . Results Difficulties existed in completing all of the measurements planned for the experiment. In the . A36 Steel Charpy V-notch measured values.-80 -60 -40 -20 0 20 40 60 80 100 0 50 100 150 200 250

Rubber compression stress relaxation Tester service

Ageing Oven service

Vacate Heating-distortion Temperature Meter service

web24 de out. de 2023 · Menina teve alta na semana passada; Nota técnica da Secretaria de Saúde confirma que outra criança morta estava com a bactéria, mas não houve confirmação em laboratório. Desde setembro .

charpy impact test results for a36 steel|charpy impact energy vs temperature